Mobilgrease XHP™ 461 helps steel plant with improved equipment reliability and minimized grease buildup success story

Réduction de la consommation de graisse de

60%

Situation

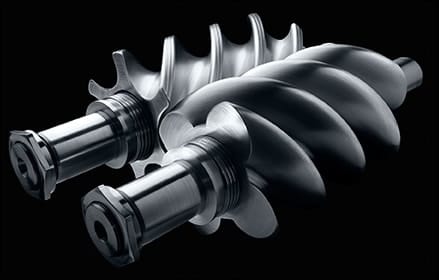

The mill used a multi-purpose lithium-based EP grease for lubricating the work roller bearing in the 3500 medium plate rolling mill. Much of the grease was removed by frequent water wash out. In addition, the grease would often become emulsified due to water condensation in the bearings. Wash out and emulsification were contaminating bearings, leading to high grease feed rates to purge water and a negative impact on bearing life in the high H20 environment.

Recommendation

The ExxonMobil Lube Engineer conducted an on-site inspection and Elastohydrodynamic (EHL) calculations and concluded that frequent bearing failures were the result of water washout and inadequate oil film thickness. Mobilgrease XHP™ 461 lithium complex grease was recommended to resist washout and improve lubricant film thickness.

Result

Since the change over to Mobilgrease XHP™ 461 lithium complex grease lubricant, no bearing failures have been reported. Grease emulsification has also been eliminated. In addition, grease consumption has decreased by 60 percent as the re-greasing intervals have been extended. Mobilgrease XHP™ 461 lithium complex grease improved the lubrication of the work roller bearing and resulted in a savings of US $61,000 annually. The benefits resulted from:

- 60 percent decrease in grease consumption

- Elimination of bearing failures due to improved lubrication protection

- Superb adhesive and water-resistant characteristics of Mobilgrease XHP™ 461 grease provided adequate lubrication and protection, even in the presence of water

*This success story is based on the experience of a single customer. Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.